The VarioShaker

Separate your bulk material as flexible as never before!

The VarioShaker is a component seperator for feeding parts in the automation process.

Bulk material with a size of 0.5 mm - 100 mm can be flexibly supplied for further processing without any changes to the VarioShaker.

Simple Comissioning.

Thanks to intuitive software.

![[Translate to English:] Varioshaker UI](/fileadmin/_processed_/e/d/csm_varioshaker-ui_zugeschnitten_633ff1e477.jpg)

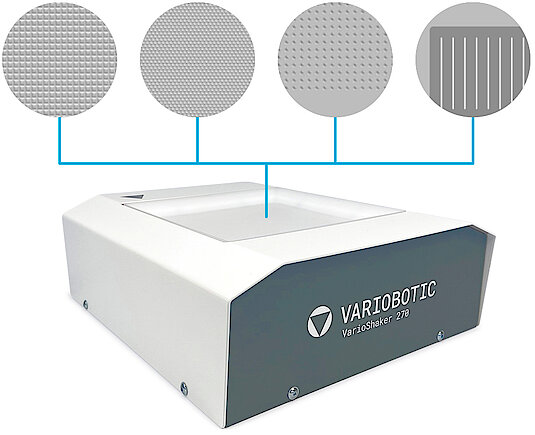

Quick-Change vibratory plates.

For many part geometries.

Fast production changeover.

Thanks to short changeover times.

Integrated transmitted light.

External light independent part detection.

Robust technology.

Almost maintenance-free.

In comparison.

classic vs. flexible part seperation.

| Classic part separation systems | Flexible part separation VarioShaker | |

|---|---|---|

| Flexiblity | - Designed for one type of component and can process them | -Designed for a wide range of components and can handle components with different geometries and weight |

| Conversion |

- Adaption to component barely possible - Conversion by experts partly possible |

- Can be converted easily and manually, without expert knowledge - Adaption to component due to different vibrating surfaces - Conversion possible by running empty |

| Quality |

- High acquisition costs - Long amortization with changing parts | - Fast amortization with changing parts |

| Process stability / availability |

- Susceptible to fluctuating components / dimensions (e.g., injection molded parts at different temperatures) - Increased downtime / fault time | - Robust and unobtrusive |